VOMATEX News

We are looking forward to meet you in hall 8.0 booth D27 at Texprocess fair in Frankfurt a.M. from 21. to 24. April 2026.

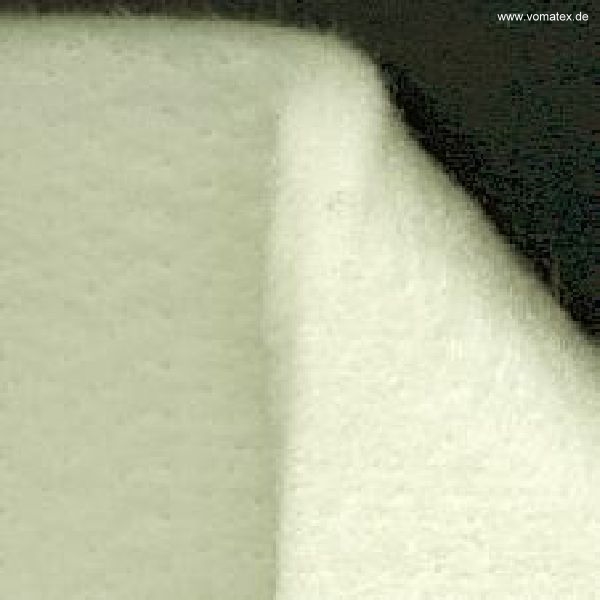

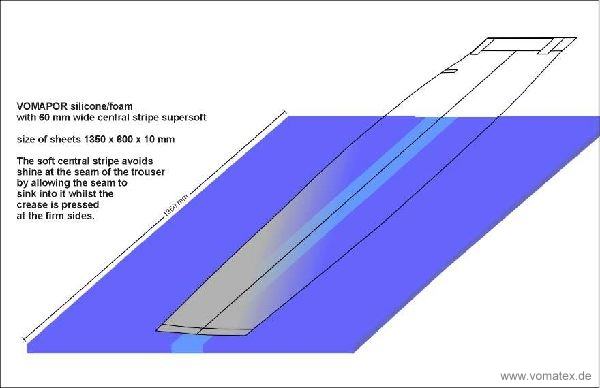

VOMATEX presents a wide range of heat and pressure resistant foams, felts and textiles.

The qualified VOMATEX staff will do their utmost to justify your trust in our German high quality products and services and confirm that VOMATEX deserves the excellent reputation at the international clothing industry.