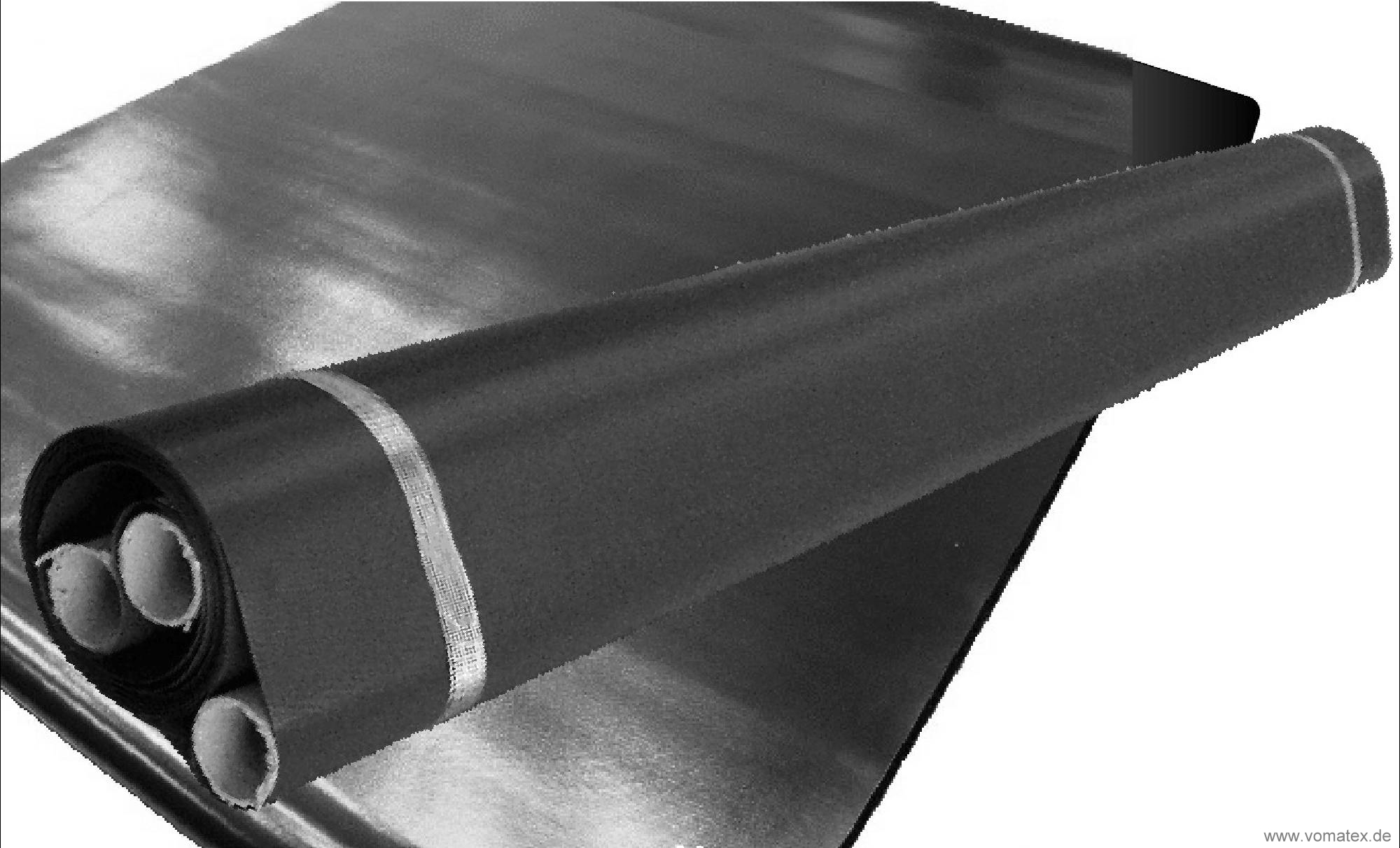

Ready Made Transport Belts

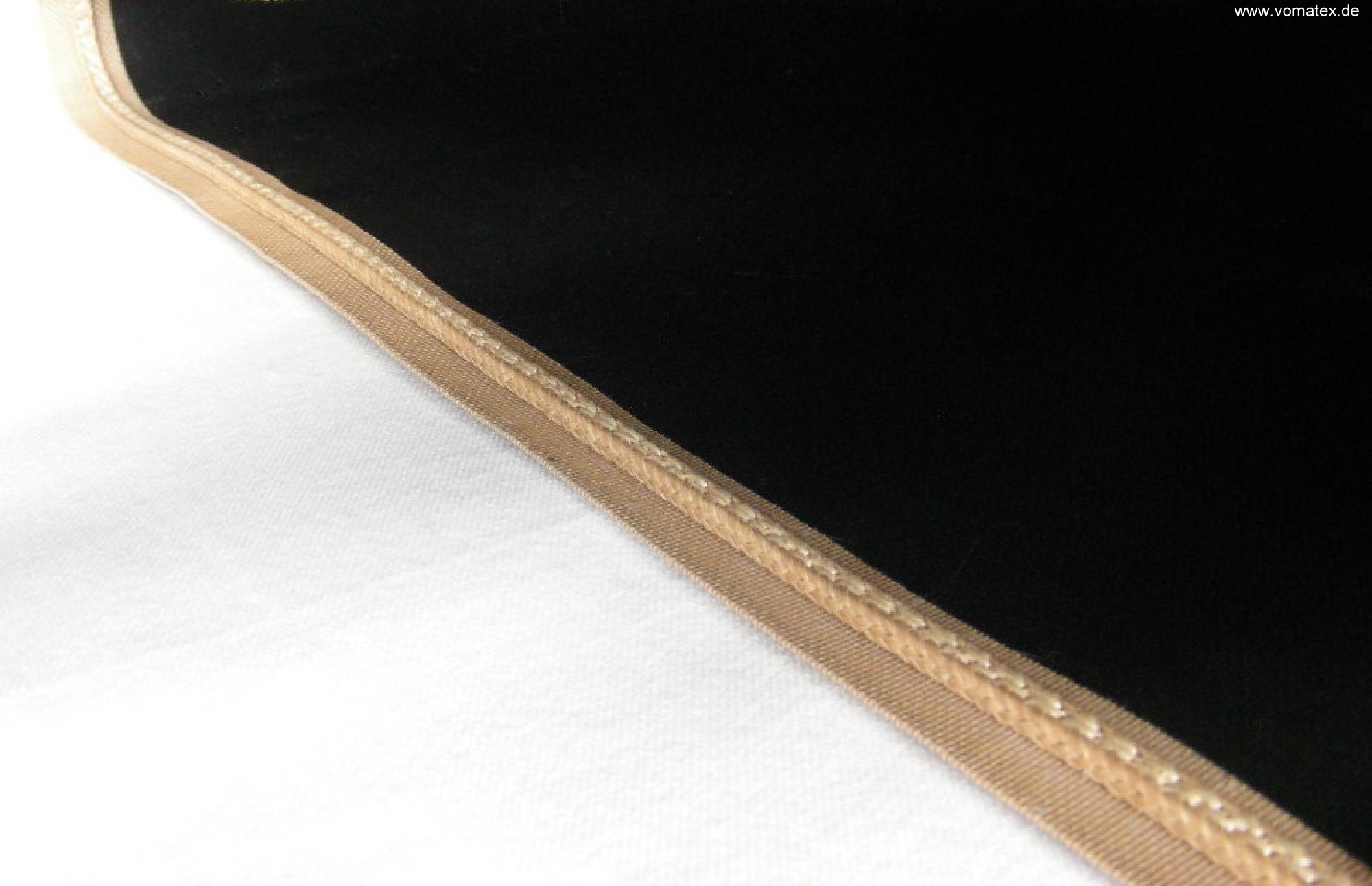

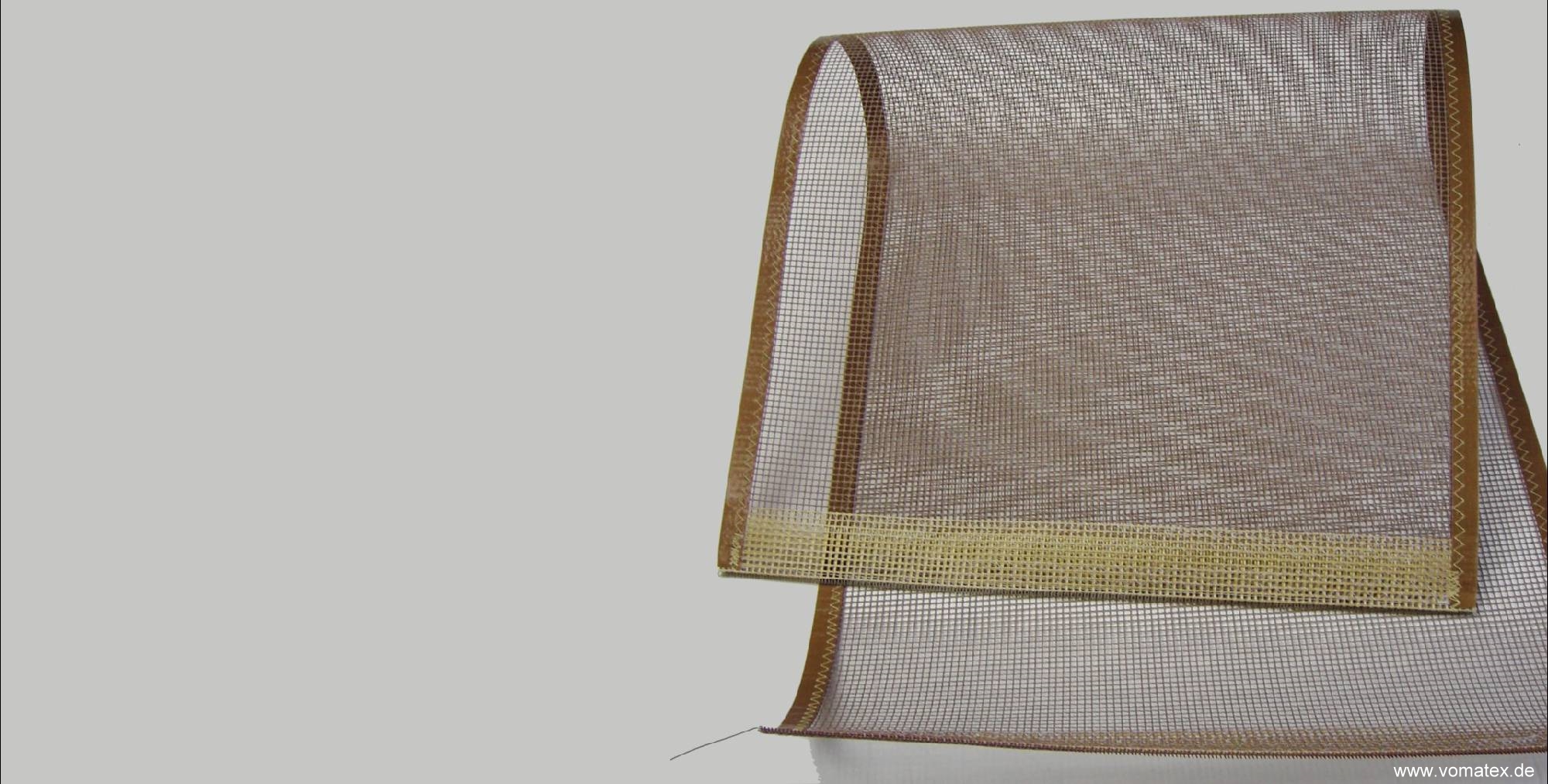

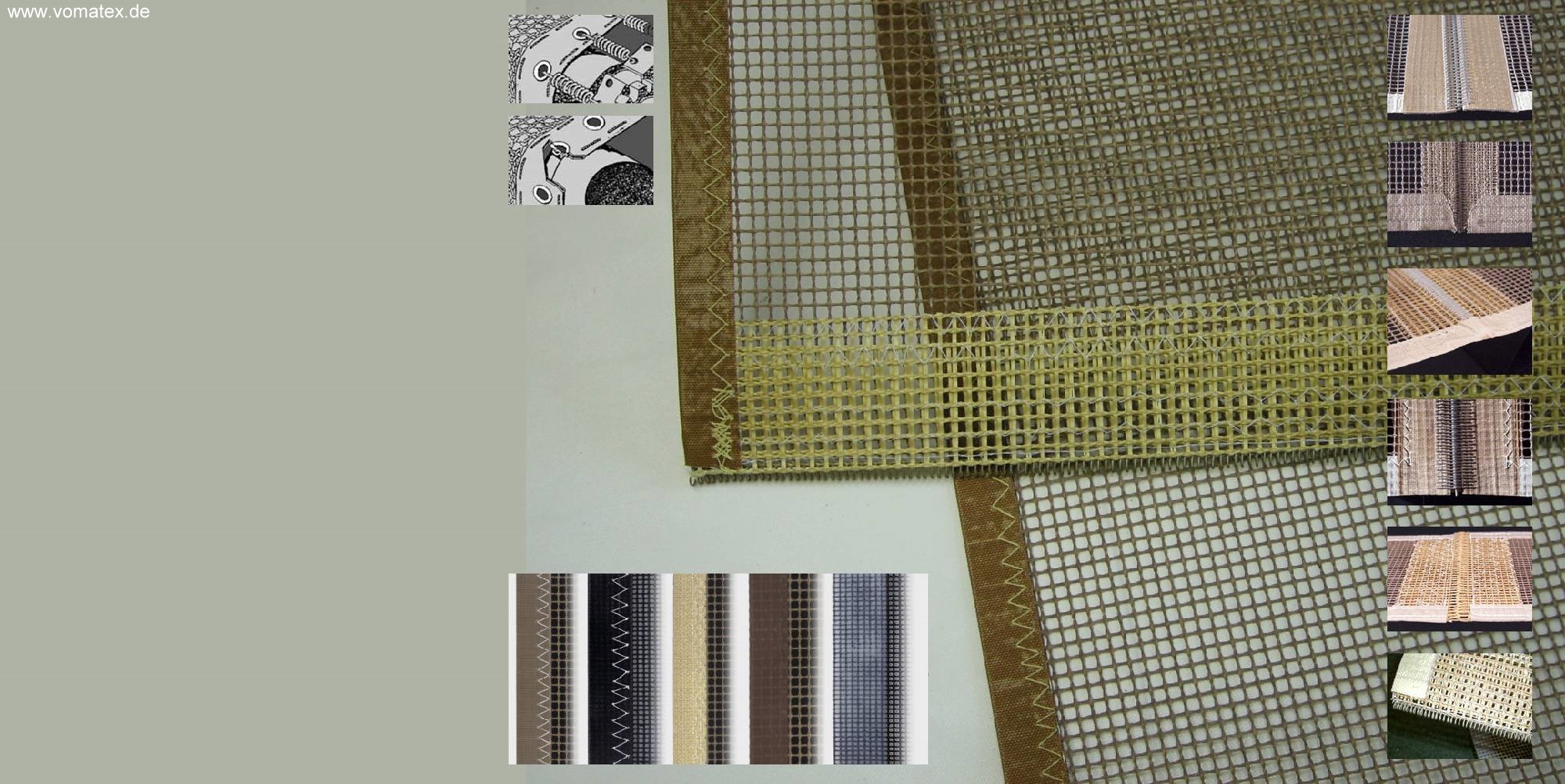

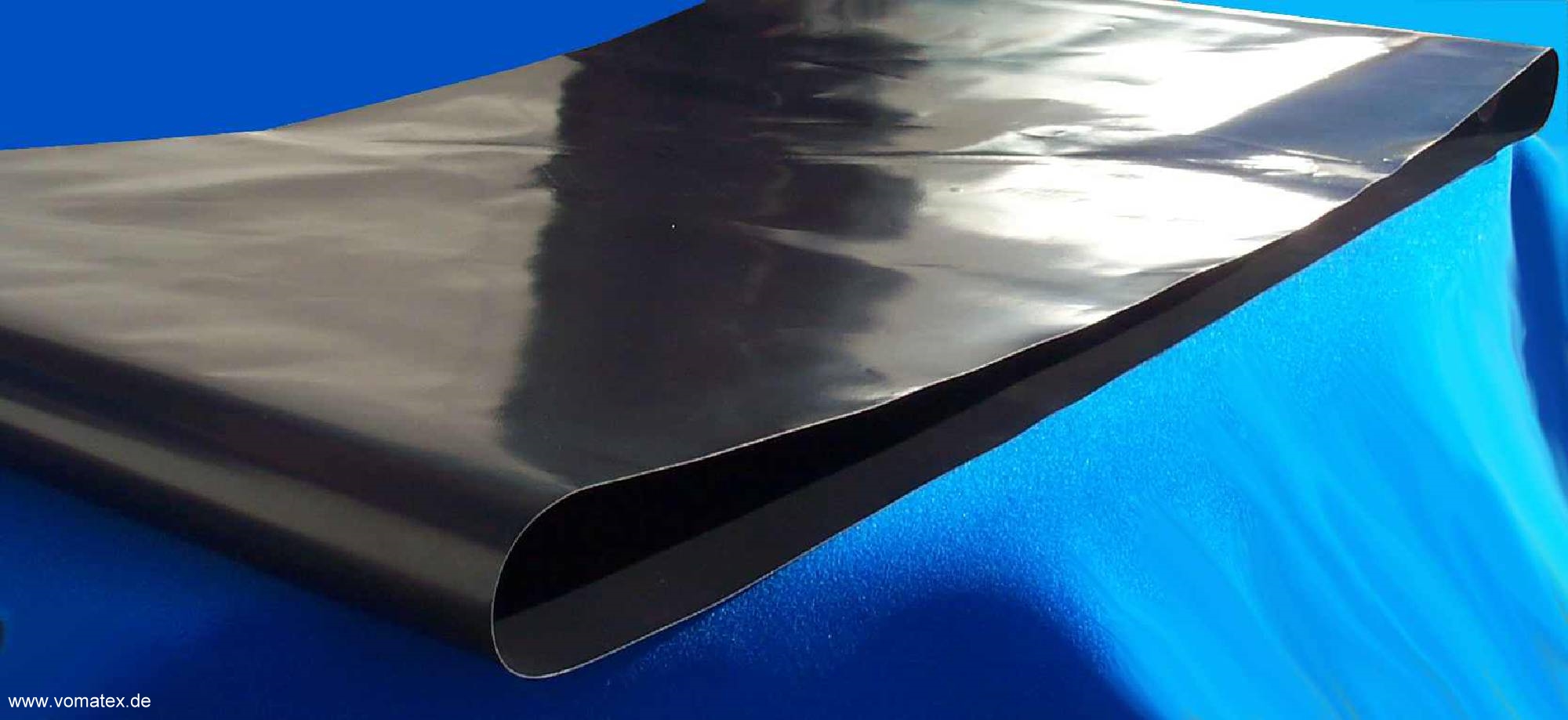

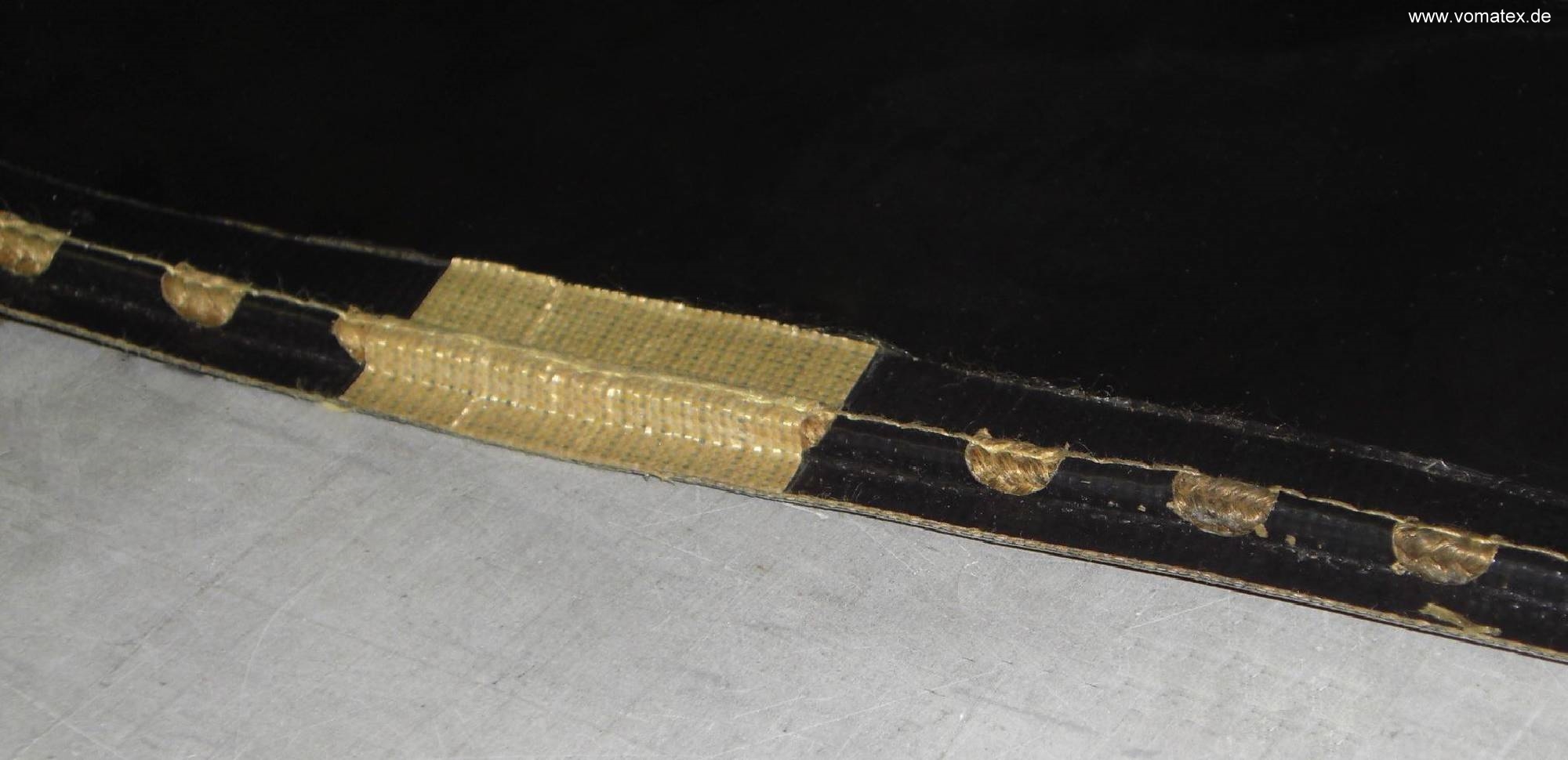

VOMATEX supplies different kinds of transport belts e.g. for fusing machines, drying machines and shrinking machines.

The belts are custom made according to the dimensions you submit to us.

Almost every type of belt for the textile industry can be supplied.